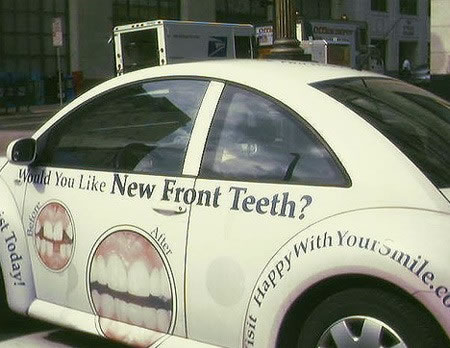

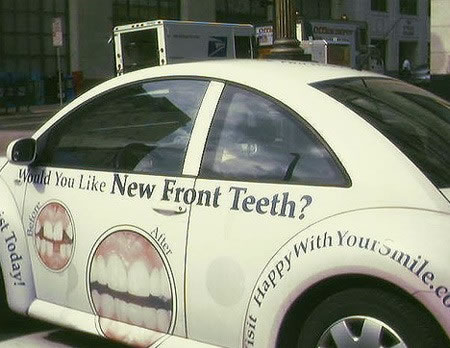

With gas getting into the realms of luxury liquid, the prices of gas prices going lower than even a cent and the chances of your salary doubling are next to nil. So what of your car is made to pay for its own gas? Wouldn’t that be a lovely thought? There are a number of advertising companies who are more than willing to get their signboard innovatively placed, in this case plastered on your car. These companies happily pay up huge amounts to the right people. However there is a reason you don’t see many of these driving billboards, because the companies with the money are looking for people who travel a lot and park their car in interesting places.

Don’t you wish your car would run on something that isn’t a rare commodity? Like something as free as air? Well with the prices of gasoline reaching new scales everyday it’s no wonder that a group of scientists have now developed cars that actually need air as a fuel, promising to run at great speeds. Mechanical engineering students from Canada’s Dalhousie University have unveiled their air-powered go-kart. Under their year-long research project, these five Dalhousie mechanical engineering students have developed compressed air engine of their own. The students modified a 40-year-old snowmobile engine and ran compressed air through the engine to produce power similar to a gas engine. They attached the engine to a refurbished go-kart using two scuba tanks to house the air. The air is released through a standard scuba fitting with a high-flow regulator. The released air travels through tubing to a ball-valve connected to the foot pedal and throttle.

The next time you get a red carpet treatment its time you show some class by demanding a greener way to arrive in style. Car rental companies are choosing Hybrid car services to pick up or drop their clients, this way they provide their clients the coveted white glove treatment with a green car. It is now widely accepted by privileged clients to get the green treatment without sacrificing on comfort, the number of limo companies offering hybrid pick-ups is rising. Clients are collected in a hybrid Ford Escape in D.C. and a hybrid Lexus in another city.

DHL has initiated a GoGreen initiative to encourage its workforce to cut their carbon footprint by 30% before 2020. By switching off the lights at DHL offices worldwide it estimates it will reduce 5.2 metric tones of carbon dioxide. This includes offices across the UAE, Bahrain, Qatar, Oman, Middle East and North Africa – is part of the company’s GoGreen Program that was launched in April this year. The program brings together all elements of its climate change initiatives and will work to improve DHL’s carbon efficiency. “Lights Off” aims to increase the environmental awareness of DHL employees and promotes the responsible use of energy. The company encourages staff to adjust their daily habits in terms of paper, water and resource usage thereby contributing to making it a more environmentally-friendly company.

DHL has initiated a GoGreen initiative to encourage its workforce to cut their carbon footprint by 30% before 2020. By switching off the lights at DHL offices worldwide it estimates it will reduce 5.2 metric tones of carbon dioxide. This includes offices across the UAE, Bahrain, Qatar, Oman, Middle East and North Africa – is part of the company’s GoGreen Program that was launched in April this year. The program brings together all elements of its climate change initiatives and will work to improve DHL’s carbon efficiency. “Lights Off” aims to increase the environmental awareness of DHL employees and promotes the responsible use of energy. The company encourages staff to adjust their daily habits in terms of paper, water and resource usage thereby contributing to making it a more environmentally-friendly company.

The next time you think of going on a vacation to the Bahamas, maybe stop and consider an environmentally friendly resort in order to contribute in reducing your own carbon footprint. One such resort is the Star Island in the Bahamas, which has the distinction of being entirely energy self sufficient. It generates its power from solar, wind and micro-hydro generators, furthermore the resort’s construction, interior and grounds have also been planned so that its details are environmentally sustainable. The luxury resort is a 10-minute boat ride from Harbour Island, near Eleuthera, and combines private homes, resort residences and bungalows with leisure facilities like a spa, restaurants, bars, pools and a “no fuel” marina. Guests can get in touch with nature through outdoor activities such as diving, sailing and deep-sea fishing. The building’s structure is designed to meet or exceed LEED requirements, through the use of materials such as cold formed steel (CFS), a mostly recycled material which relies on its manufacturing process to give it the same strength as virgin steel. The heat-free manufacturing process also reduces its carbon footprint. Additionally, construction time, shipping demands and waste are reduced through the use of insulated concrete forms – lightweight forms that are filled with concrete on site.

Brazil sugarcane workers are soon to feel the corporate axe, Brazilian Sugar Cane Industry Association (UNICA) said 80% of the 500,000 jobs would be gone within three years and admitted that moving to a tractor-based system would cause pain and upheaval for its migrant workforce. Behind the move to phase out sugar cane cutters are tales of exploitation that have damaged the image of Brazilian biofuels in big importing countries such as Sweden and potentially in Britain, where the government has mandated that 2.5% of all petrol come from biofuels. The condition of sugar workers was rarely noticed when the commodity was exported for sugar but the position has changed now that Brazil is the world’s second-largest exporter of sugar-based ethanol to use as a biofuel in petrol. Sugar cane cutters who have been working Brazil’s land since 1525, when Portuguese colonialists first experimented with growing the crop, are to make way for mechanization. Manual labor is also blamed for poor environmental practices such as crop wastage and the burning of stubble.

The United Nations kick started this year’s World Environment Day by urging the world to kick an all-consuming addiction to carbon dioxide and said everyone must take steps to fight climate change. U.N. Secretary-General Ban Ki-Moon said global warming was becoming the defining issue of the era and will hurt rich and poor alike. World Environment Day, conceived in 1972, is the United Nations’ principal day to mark global green issues and aims to give a human face to environmental problems and solutions. Global carbon emissions from burning fossil fuels are rising quickly and scientists say the world faces rising seas, melting glaciers and more intense storms, droughts and floods as the planet warms.

Find yourself looking at bus schedules instead of a trip to the gas station? The rise of gasoline prices, coming at a time when most Americans are tightening their belts, has led to a spike in demand for public transit. This in turn is great for the environment as more people choose environment friendly alternatives than their gas guzzling 4x4s and Humvees for everyday transit.

Sarah Featherstone’s cutting-edge green home has been sold for a record-breaking $14.2million USD! The building, known as Orchid House, is one of the key homes on Lower Mill Estate, a project to turn a disused gravel pit into a beautiful 450-acre nature reserve. At $5800 per square foot, its one of the pricey real estate markets in the UK. The aim of the building is to produce more energy than it consumes by way of geothermal heating. The form is created using laminated veneer lumber which is more long lasting than conventional timber but isn’t too great for the environment.

If you feel that a rainy day is an opportunity for water harvesting and aren’t keen with the upside-down umbrella that collects water, a more practical solution is in the works. The FilterBrella actually collects water on the move in the handle which acts a portable bottle. The canopy is made of compostable polylactic acid plastic blends, which makes it environment friendly. Adding to the environmental friendliness is the innovative activated carbon filter in its hollow rod. The hollow rod actually lets in rainwater, which, then gets purified by the activated carbon.